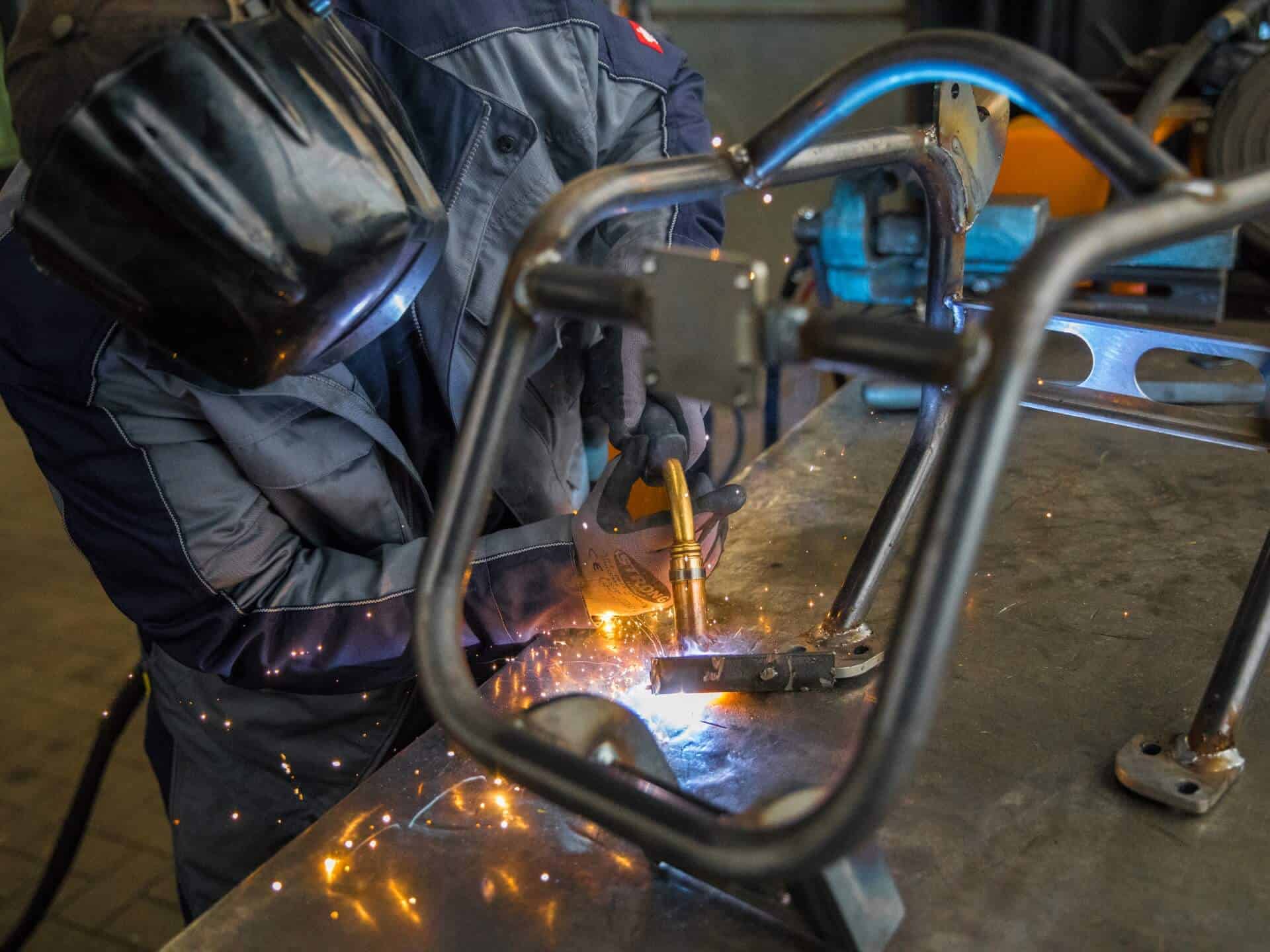

For more than 30 years, RESPONDECK and its 50 employees strive to provide high quality metalworking in the machining and forming sector. As a contract manufacturer and supplier with a state-of-the-art machine park, we bend, mill, turn, roll, weld and saw a wide variety of metals for medium-sized customers from the region as well as large international corporations—across industries, from prototyping to assemblies to large series.

As a reliable partner, we support you in reducing your vertical integration and suppliers. Benefit from our extensive experience in project planning and production of individual solutions or use our comprehensive range of services as an extended workbench. Our lean structure and continuous process optimization enable high adherence to deadlines and fast turnaround times—from expert advice on design and production engineering issues to storage and shipping.

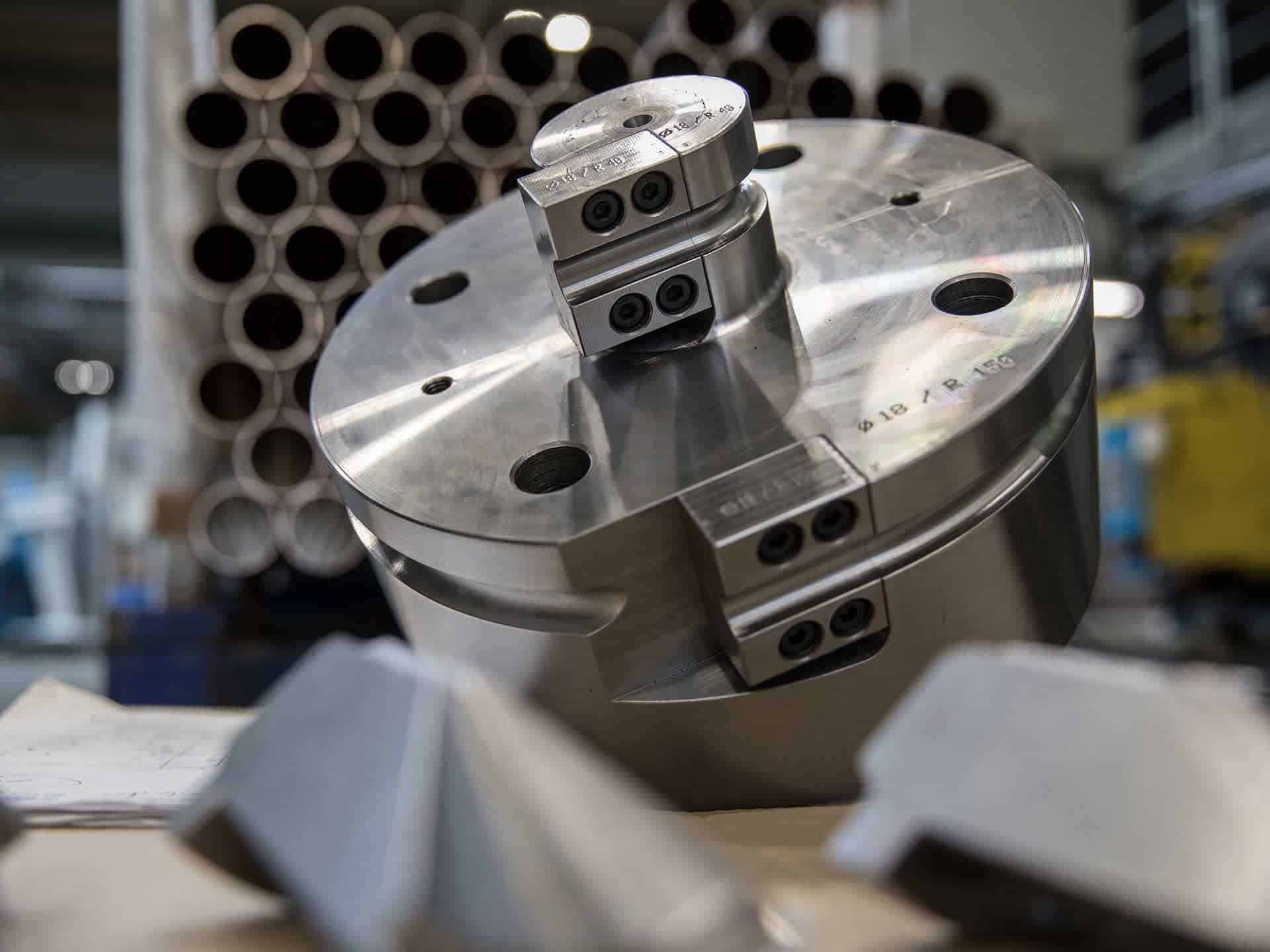

We rely exclusively on quality machines for our work in the machining and forming sector. All systems are regularly serviced, overhauled and meet the highest technical and qualitative requirements. In conjunction with our CAD/CAM workstations and three advanced measuring systems, we can provide you with solutions precisely tailored to your areas of application.

Due to constant customer growth and ever new requirements, we have continued to increase our vertical integration over the last few years. However, we continue to implement certain customer requests that require particularly complex or cost-intensive production processes with certified partners from the region—including lasering, powder and CDP coating, hardening or annealing.

We make no compromises when it comes to material procurement: We don’t buy wherever it’s cheap, but have been buying from the German market leaders in the premium segment for years. In the tube sector, in addition to Wieland-Werke AG and BENTELER Steel/Tube, this is primarily Schoeller in Hellenthal. Thanks to the close business relationships, you as a customer benefit from economical prices and short delivery times even during difficult market conditions.